Testing and Analytics

SEL’s independent scientific and engineering services are trusted by industry and regulators, with decades of experience and rigorous scientific standards.

SEL’s CT Scanner has a 225 kv x-ray source and a 127 micron Varian detector, allowing for excellent image resolution as low as single digit microns. The CT Scanner provides high quality imagery showing detailed internal characteristics of devices and components for non-destructive examination. CT Scanning is increasingly valuable in the forensic examination of personal electronics, batteries and fire damaged artifacts, but is also key in many industrial inspection situations.

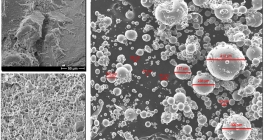

The Scanning Electron Microscope (SEM) is a key investigative and analysis tool. Its relatively large specimen chamber (up to 6 inches in diameter) means that substantial samples can be viewed at magnifications up to 168,000x. The instrument features an energy dispersive x-ray analysis spectrometer (EDS), which allows elemental identification of materials.

Optical stereomicroscopes and metallurgical microscopes aid in the viewing and documenting of small artifacts and/or mounted cross-sections.

SEL’s sample preparation capabilities include sample mounting, cutting, grinding, polishing, and the etching of metallurgical artifacts. An ultrasonic cleaning bath and a variety of cleaning solvents and agents are available if necessary.

A Fourier Infrared Spectrophotometer (FTIR) is used for precise structural identification of organic solid, liquid and gas samples. The FTIR, with libraries containing over 5000 spectra, can be used to quickly determine the composition of virtually any organic sample. Some of the samples, which can easily be examined with the FTIR, include: plastics, films, oils, solvents, pastes, waxes, gases, and combustion products. The FTIR at SEL has a long path length gas cell and time-resolved software, which allows for the collection of spectra of a gaseous sample over time with the collection interval variable. This permits dynamic analysis and offers the ability to create a time-resolved profile of the combustion process.

Portable and stationary digital x-ray systems permit the radiographic examination of both artifacts and items that can be brought to our facilities and those that cannot be transported.

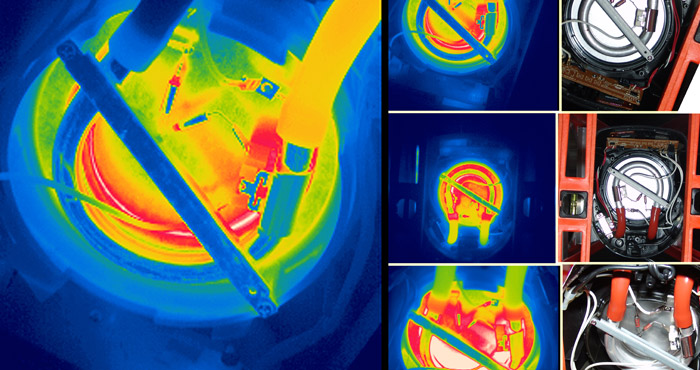

For testing and analysis of customer products, SEL has an extremely versatile, high performance ThermaCam™ system – a thermal imaging radiometer. The ThermaCam shoots both video and still digital images and provides accurate temperature measurement of any pixel in the scene.

Data logging capabilities allow for the recording and analysis of electrical and thermal characteristics during normal operation and abuse scenarios. A test room at our Yale, Michigan site is equipped with comprehensive computer data retrieval and analysis systems. Also at our Yale site, SEL can construct full-scale structures for demonstrations.

SEL can conduct more than 60 national and international standards tests for product and systems safety including:

Standardized DOT and FAA testing

Standardized flammability testing

Elemental analysis of materials and compounds

Equipment and appliance testing

Determination of material combustibility and explosive properties

Impact of fire retardant chemicals and devices

Rate of heat and smoke release

Determination of presence and levels of products of combustion

Testing for hazard potential

Testing for mechanical or electrical failure